Finger Joint Board are used popularly in building and construction in many countries. SZBOARD offer wide range of FJLB including AA, AB, AC, BC grade with thickness available from 8 mm – 80mm.

Rubberwood also known as Plantation Hardwood is the standard common name for the hardwood timber of Hevea brasiliensis.

Rubberwood has a dense grain that is easily controlled in the kiln drying process. Rubber-wood has very little shrinkage making it one of the more stable construction materials available for furniture, toys and kitchen accessories.

Rubberwood is used only after it completes its latex producing cycle, generally when it is 25-30 years old. When the latex yields become extremely low, the trees are then felled, and new ones are usually planted. This wood is therefore eco-friendly in the sense that it is being used when it would normally be thrown away.

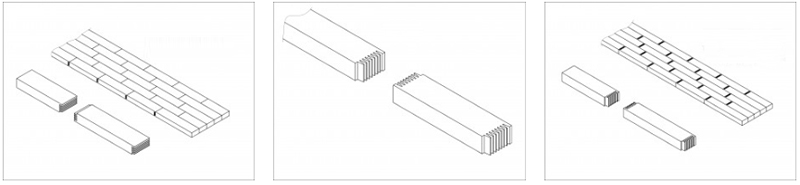

Finger joint laminated board (FJL board) is a solid wood board made by combining many laminas by finger joint or butt joint method into usable lengths strips. These strips are then pressed and laminated together by special glues (2 components adhesive) by hydraulic press machines to become the finger joint laminated board. The laminated board has many advantages that solid wood conventionally does not have. For instance, warping or twisting, which occurs in woodwork manufacturing process could be avoided if we use laminated board instead of solid wood.

Show Zone Wood partners with many kiln dry timber suppliers; therefore we can assure stable quality and quantity of rubber wood raw material. After air drying, the moisture of rubber wood sawn timber is around 10% (+-2%).

The length of FJL Board can be up to 4 meters and the width can be up to 1,25m. The board after finger jointing and laminating has to pass all the delamination tests at Show Zone Wood. Also, we can provide customized products based on requests from customers such as uniform lamina pitch per board, cut to size or edge sanding. These customizations are usually used for DIY products.

Quality control (QC) is one of our strength because we have QC procedure for the whole process of making products and one more QC step for final inspection. ISO 9001-2008 and JAS MALQ/G 01-LF/007 are applied to manage the whole factory in a sufficient condition which can result in cutting down the cost. JAS Label per bundle and JAS Label per piece are also provided if customers required.

| Color/Appearance: | Heartwood naturally a light blonde to medium tan color, sometimes with medium brown streaks. Sapwood not distinct from heartwood. Color tends to darken slightly with age. Frequently colored or stained when used in furniture construction. |

| Grain/Texture: | Grain is straight, with a somewhat coarse, open texture. Low natural luster. |

| Rot Resistance: | Rubberwood is perishable, and has very little natural resistance to decay. It is also susceptible to fungal staining and insect attacks. |

| Workability: | Easy to work with both hand and machine tools. Rubberwood tends to warp and twist in drying, though it is fairly stable in service once seasoned. Glues, stains, and finishes well. |

| Allergies/Toxicity: | There have been no adverse health effects associated with Rubberwood in particular. However, individuals with natural latex or rubber allergies may have reactions to Rubberwood. See the articles Wood Allergies and Toxicity and Wood Dust Safety for more information. |

| Sustainability: | This wood species is not listed in the CITES Appendices or on the IUCN Red List of Threatened Species. Rubberwood lumber is typically taken from rubber plantations where the trees are tapped for latex, and harvested at the end of their useful life cycle. |

| Common Uses: | Furniture, cabinetry, interior millwork, kitchen woodware (cutting boards, knife blocks, etc.), and other small, specialty wood items. |

Copyright©2022-2023.Show Zone Wood All Rights Reserved.